| Quantity: 3 Tons |

| Diameter: 1.2~3mm |

| Length: 1000mm |

| Material: Aluminum Alloy |

ER5183 Aluminum Alloy Welding Wire

ER5183 Aluminum alloy welding wires are used in various applications where joining aluminum components is required. These components can include structures in the automotive industry, aerospace industry, construction, and more. ER5183 is particularly known for its good corrosion resistance and high strength. It's often used to weld aluminum alloys of similar composition, such as 5083 and 5456.

Here are some key characteristics and properties of ER5183 aluminum alloy welding wire:

Composition: ER5183 contains primarily aluminum with the addition of magnesium as the main alloying element. This composition provides improved strength and corrosion resistance compared to some other aluminum alloys.

Applications: ER5183 is commonly used for welding aluminum-magnesium alloys, especially in marine and structural applications, where corrosion resistance is critical. It's suitable for joining materials that are often exposed to harsh environments.

Welding Process: This welding wire is typically used in the Gas Metal Arc Welding (GMAW) or Metal Inert Gas (MIG) welding process, which involves using a consumable electrode to create a weld. It can also be used in Gas Tungsten Arc Welding (GTAW) or Tungsten Inert Gas (TIG) welding processes.

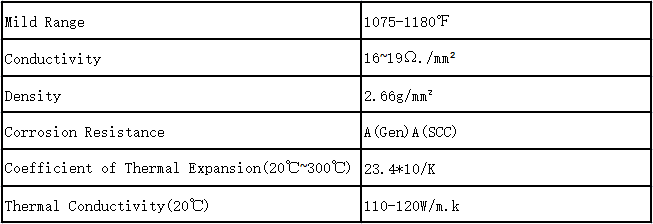

Typical Characteristics

BACK TO TOP